Page 439 - Demo

P. 439

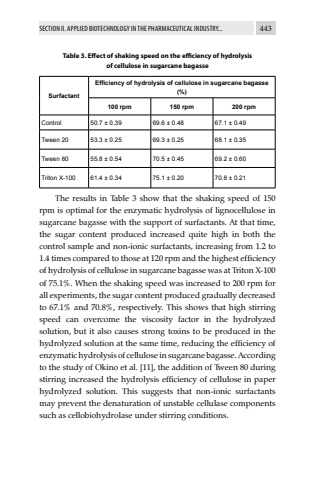

SECTION II. APPLIED BIOTECHNOLOGY IN THE PHARMACEUTICAL INDUSTRY... 443Table 3. Effect of shaking speed on the efficiency of hydrolysis of cellulose in sugarcane bagasseSurfactantEfficiency of hydrolysis of cellulose in sugarcane bagasse (%)100 rpm 150 rpm 200 rpmControl 50.7 %u00b1 0.39 69.6 %u00b1 0.48 67.1 %u00b1 0.49Tween 20 53.3 %u00b1 0.25 69.3 %u00b1 0.25 68.1 %u00b1 0.35Tween 80 55.8 %u00b1 0.54 70.5 %u00b1 0.45 69.2 %u00b1 0.60Triton X-100 61.4 %u00b1 0.34 75.1 %u00b1 0.20 70.8 %u00b1 0.21The results in Table 3 show that the shaking speed of 150 rpm is optimal for the enzymatic hydrolysis of lignocellulose in sugarcane bagasse with the support of surfactants. At that time, the sugar content produced increased quite high in both the control sample and non-ionic surfactants, increasing from 1.2 to 1.4 times compared to those at 120 rpm and the highest efficiency of hydrolysis of cellulose in sugarcane bagasse was at Triton X-100 of 75.1%. When the shaking speed was increased to 200 rpm for all experiments, the sugar content produced gradually decreased to 67.1% and 70.8%, respectively. This shows that high stirring speed can overcome the viscosity factor in the hydrolyzed solution, but it also causes strong toxins to be produced in the hydrolyzed solution at the same time, reducing the efficiency of enzymatic hydrolysis of cellulose in sugarcane bagasse. According to the study of Okino et al. [11], the addition of Tween 80 during stirring increased the hydrolysis efficiency of cellulose in paper hydrolyzed solution. This suggests that non-ionic surfactants may prevent the denaturation of unstable cellulase components such as cellobiohydrolase under stirring conditions.