Page 529 - Ebook HTKH 2024

P. 529

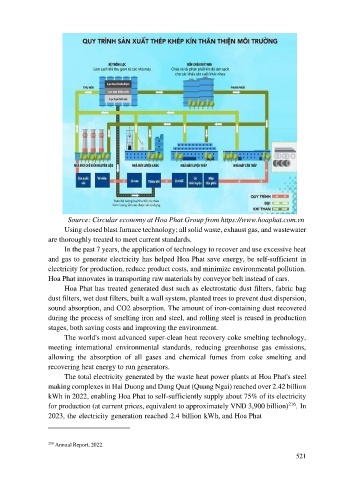

Source: Circular economy at Hoa Phat Group from https://www.hoaphat.com.vn

Using closed blast furnace technology; all solid waste, exhaust gas, and wastewater

are thoroughly treated to meet current standards.

In the past 7 years, the application of technology to recover and use excessive heat

and gas to generate electricity has helped Hoa Phat save energy, be self-sufficient in

electricity for production, reduce product costs, and minimize environmental pollution.

Hoa Phat innovates in transporting raw materials by conveyor belt instead of cars.

Hoa Phat has treated generated dust such as electrostatic dust filters, fabric bag

dust filters, wet dust filters, built a wall system, planted trees to prevent dust dispersion,

sound absorption, and CO2 absorption. The amount of iron-containing dust recovered

during the process of smelting iron and steel, and rolling steel is reused in production

stages, both saving costs and improving the environment.

The world's most advanced super-clean heat recovery coke smelting technology,

meeting international environmental standards, reducing greenhouse gas emissions,

allowing the absorption of all gases and chemical fumes from coke smelting and

recovering heat energy to run generators.

The total electricity generated by the waste heat power plants at Hoa Phat's steel

making complexes in Hai Duong and Dung Quat (Quang Ngai) reached over 2.42 billion

kWh in 2022, enabling Hoa Phat to self-sufficiently supply about 75% of its electricity

for production (at current prices, equivalent to approximately VND 3,900 billion) 216 . In

2023, the electricity generation reached 2.4 billion kWh, and Hoa Phat

219 Annual Report, 2022.

521