Page 187 - Ebook HTKH 2024

P. 187

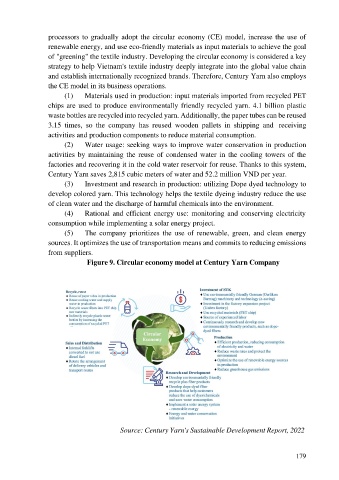

processors to gradually adopt the circular economy (CE) model, increase the use of

renewable energy, and use eco-friendly materials as input materials to achieve the goal

of "greening" the textile industry. Developing the circular economy is considered a key

strategy to help Vietnam's textile industry deeply integrate into the global value chain

and establish internationally recognized brands. Therefore, Century Yarn also employs

the CE model in its business operations.

(1) Materials used in production: input materials imported from recycled PET

chips are used to produce environmentally friendly recycled yarn. 4.1 billion plastic

waste bottles are recycled into recycled yarn. Additionally, the paper tubes can be reused

3.15 times, so the company has reused wooden pallets in shipping and receiving

activities and production components to reduce material consumption.

(2) Water usage: seeking ways to improve water conservation in production

activities by maintaining the reuse of condensed water in the cooling towers of the

factories and recovering it in the cold water reservoir for reuse. Thanks to this system,

Century Yarn saves 2,815 cubic meters of water and 52.2 million VND per year.

(3) Investment and research in production: utilizing Dope dyed technology to

develop colored yarn. This technology helps the textile dyeing industry reduce the use

of clean water and the discharge of harmful chemicals into the environment.

(4) Rational and efficient energy use: monitoring and conserving electricity

consumption while implementing a solar energy project.

(5) The company prioritizes the use of renewable, green, and clean energy

sources. It optimizes the use of transportation means and commits to reducing emissions

from suppliers.

Figure 9. Circular economy model at Century Yarn Company

Source: Century Yarn's Sustainable Development Report, 2022

179